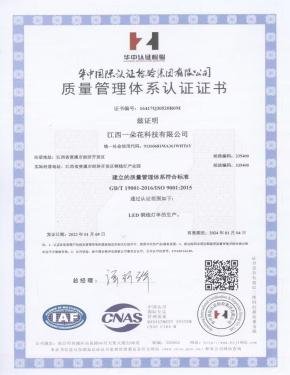

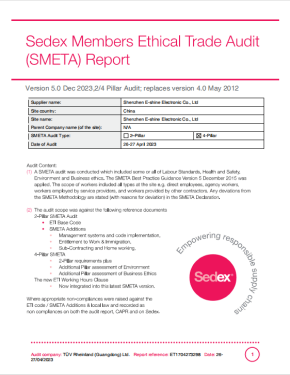

ISO Compliant Production Cycle

Our manufacturing system is designed to be dust-free and undergoes rigorous supervision to uphold the highest standards of quality.

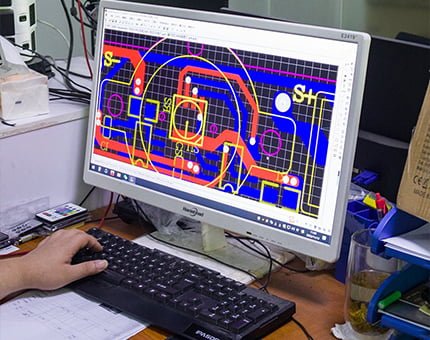

This initial phase involves engineers and designers collaborating on the light string's design, considering aspects like LED color, length, and pattern.

The next step is to source the required materials, such as LEDs, wires, and casings, ensuring they meet quality standards and specifications.

Workers cut and strip wires to the necessary lengths, preparing them for assembly.

In this phase, LEDs are carefully soldered onto the wires. This step requires precision to ensure reliable electrical connections and the overall integrity of the light string.

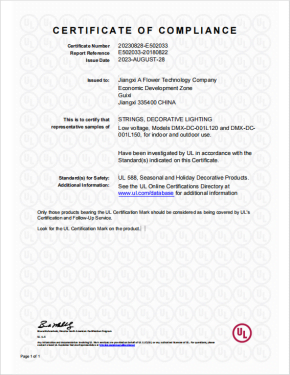

For outdoor light strings, additional steps are taken to apply waterproof coatings and insulation, protecting the lights from weather elements.

Completed light strings are thoroughly tested for functionality, durability, and safety. This quality assurance phase is crucial to ensure the products meet industry standards and customer expectations.

Finally, the light strings are packaged, often including instructions and additional components like remote controls. Packaging also involves ensuring the product is securely and attractively presented for retail.